Aerospace Manufacturer avoids $350,000 in capital expenditures through electrical capacity study enabled by ePlanet

ePlanet-supplied and supported sensors were deployed by the customer to assist with planning for equipment reconfiguration and production line expansion planning. Key equipment types, panels, and feeders were monitored, allowing the customer to verify existing infrastructure could support planned changes to production configurations.

By investing in energy monitoring through ePlanet, the site avoided an unnecessary capital project that would have required over a week of shutdown, a cost that was not even included in the ROI calculation!

The return-on-investment for this project was less than 1 month!

Manufacturing company plans for adding production, uses ePlanet to verify whether a new chiller is needed. Existing oversized chiller is enough to meet added load, avoiding $50,000 chiller replacement

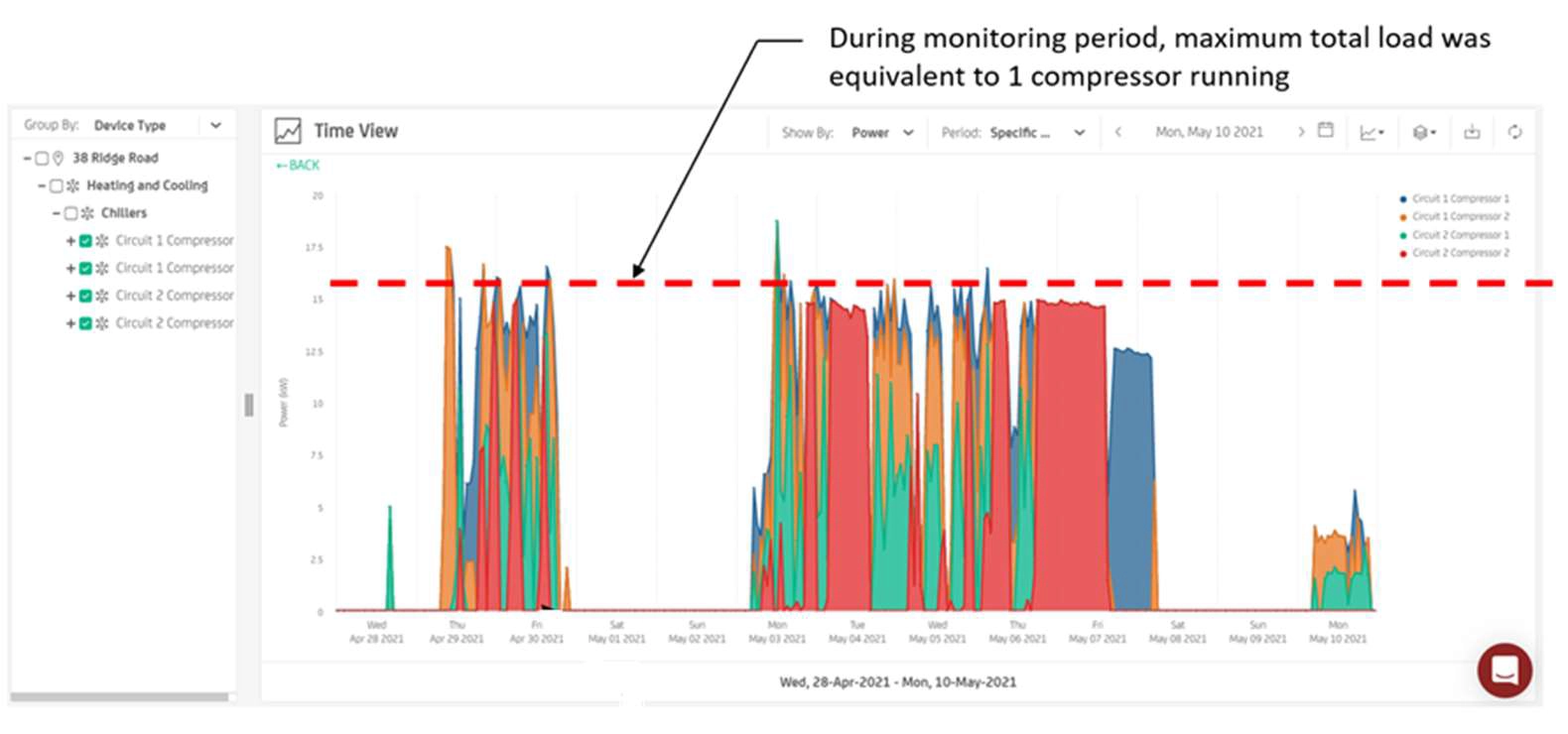

A site was skeptical of the need for a new, larger chiller to meet load from a planned expansion of production. ePlanet deployed sensors on the existing chiller's compressors to determine how the existing chiller operated. Site personnel were trained on how to view and interpret data, and ePlanet provided reviews after a few weeks of data were collected.

ePlanet determined the chiller never used more than 25% of its capacity, validating the operator's intuition that a chiller expansion was not needed. By using the existing chiller, the site avoided a potential $50,000 equipment cost, plus the time lost for production.

The return-on-investment for the installation was less than 1 month!